Precise power line inspections at up to 140 km/h

It’s no secret that electricity is essential to modern life, but for industrial applications, it is absolutely critical.

From the moment our alarm wakes us until we switch the lamp off at the end of the day, every electronic device we use at the end of a long chain of components, each reliant on power lines carrying electricity from the plant it’s generated via transformers and conductors. The device you’re reading this on is no exception!

In this complex and constant process, power lines are comparable to the arteries that keep modern society alive; a single undiagnosed problem can have huge and potentially disastrous consequences for infrastructure and industry as a whole.

Visimind, one of the world’s leading providers of georeferenced data and utility information, is using FLIR thermography to help prevent overloads and beat burnout for some of the largest companies in Europe - including leading energy giants.

FLIR thermal cameras for precision utility inspection

Visimind protects the electricity supply by inspecting power lines to ensure that threats which can pose damage or detrimental performance to components are spotted before they can spark chaos.

From environmental issues such as trees or vegetation encroaching on lines to operational problems, like loose connections or elements overheating, every element of electricity transmission must be inspected. Overhead lines and pylons through to transformers and towers must be carefully monitored to ensure optimal performance, flag any maintenance concerns and, of course, preserve safety.

Its customers include governments, public institutions, private companies and, critically, the energy companies that hold it all together.

Visimind can cover up to 400 kilometers of lines in a single day, inspecting 2000 spans between pylons and 24,000 conductors. For this demanding job, efficiency is second only to accuracy in meeting the company’s need to conduct comprehensive utility assessments.

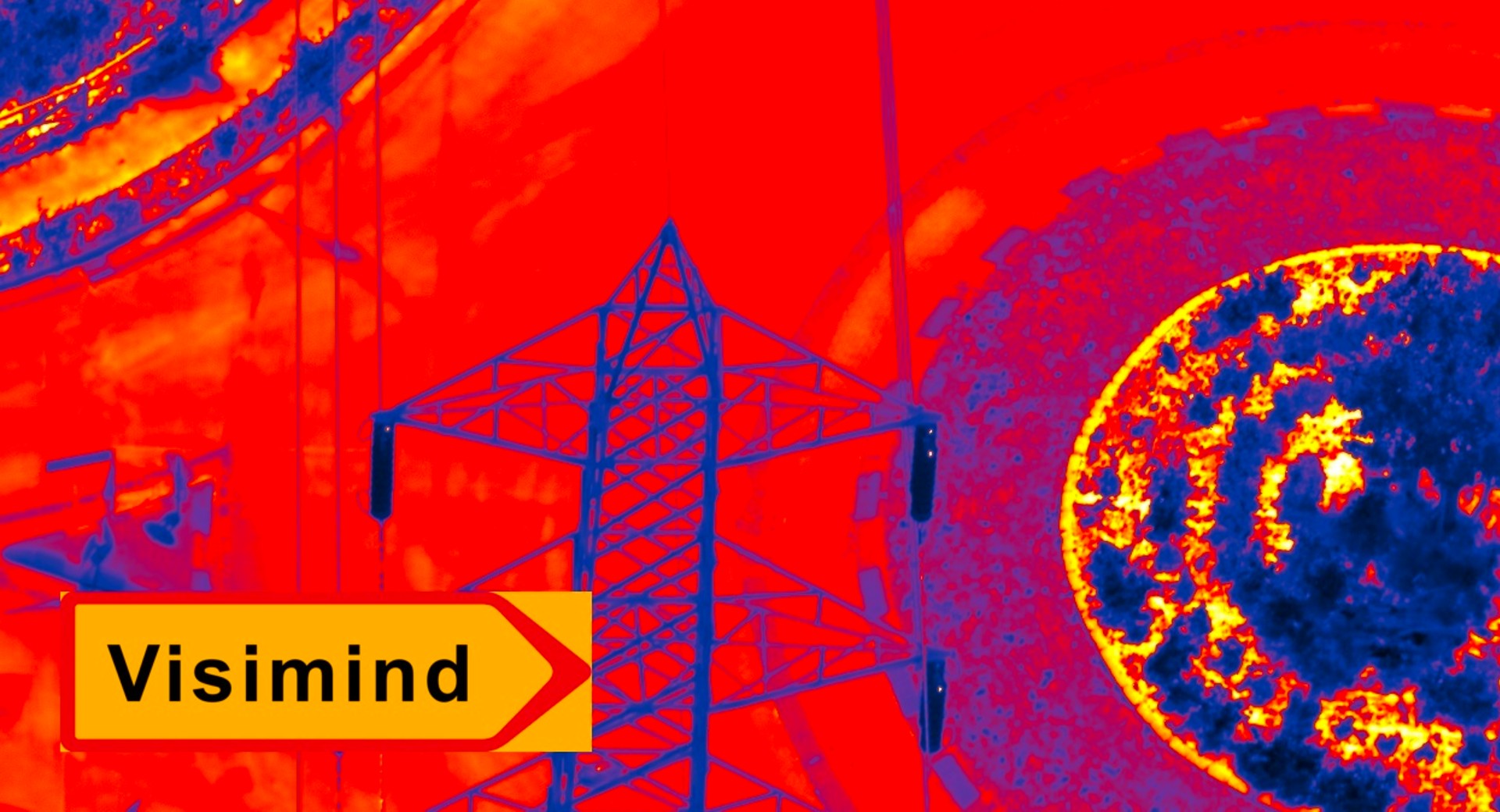

Using the latest technology such as ultra-dense 3D lidars, high-resolution cameras, and advanced FLIR thermal cameras on manned helicopter flights, Visimind is able to monitor and analyse information related to every element of the electricity transmission process in incredible detail.

Detail over distortion: delivering results in challenging conditions

The success of Visimind's inspection operations lies in its agile fleet of helicopters, including models like Hughes MD500, Eurocopter AS350, Bell 206, and Robinson R44.

This aerial capability allows it to tailor its inspection solutions to the needs of each client, achieving the best results in even the most challenging conditions.

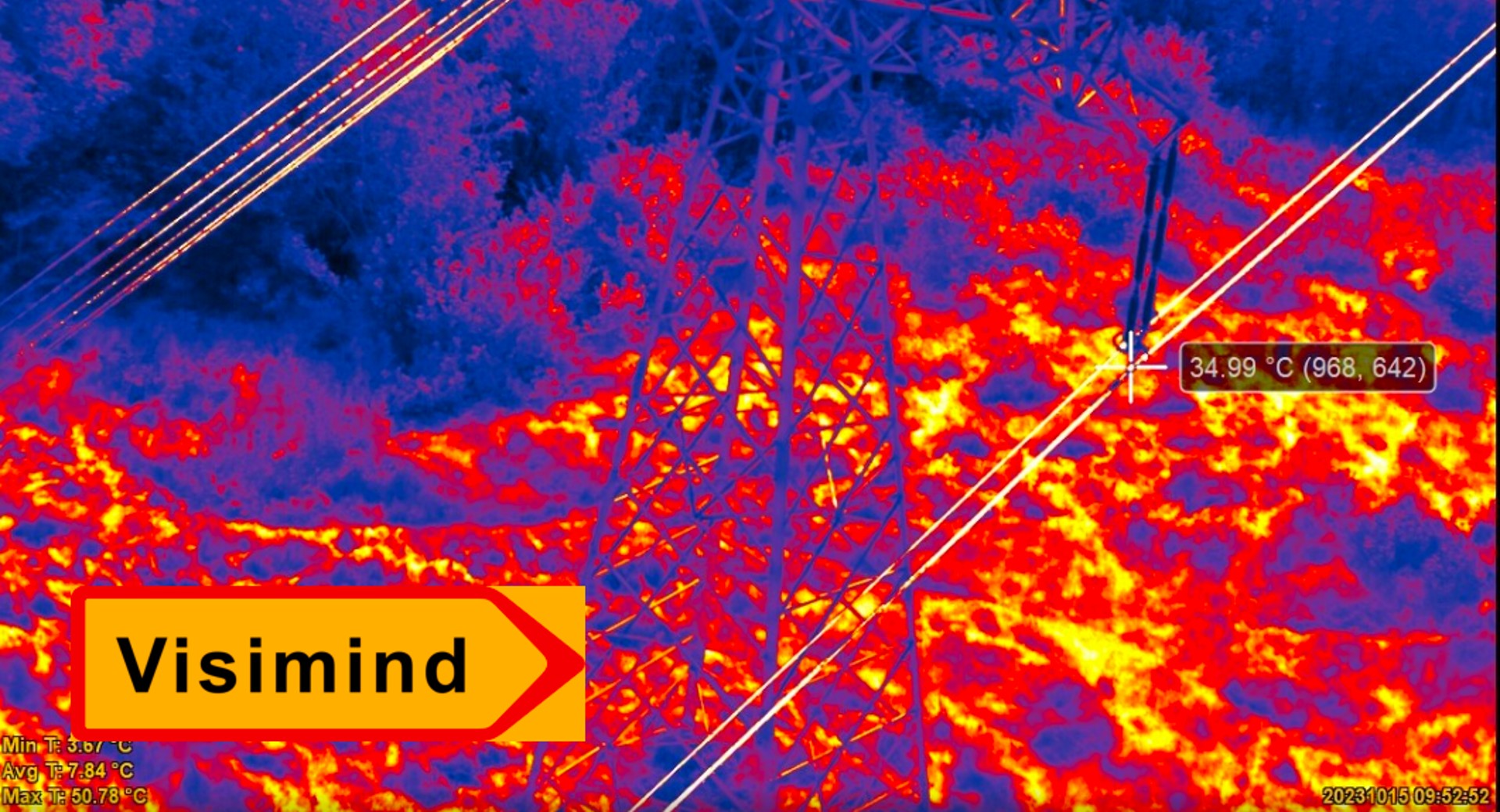

On a typical aerial inspection, flight altitudes can range from 50 up to 120 meters above objects undergoing inspection. However, travelling speeds of up to 140 km/h as well as fighting wind resistance and other environmental issues can make precision data collection a problem - without the right technology, that is.

The FLIR A8581 ensures Visimind is always upwind of potential problems

Blurring, distortion and a lack of clarity pose a real threat to at-speed inspections. One of the key reasons Visimind opted for the FLIR A8581 thermal camera is its exceptional resolution, which, combined with a telephoto lens, provides an abundance of detail.

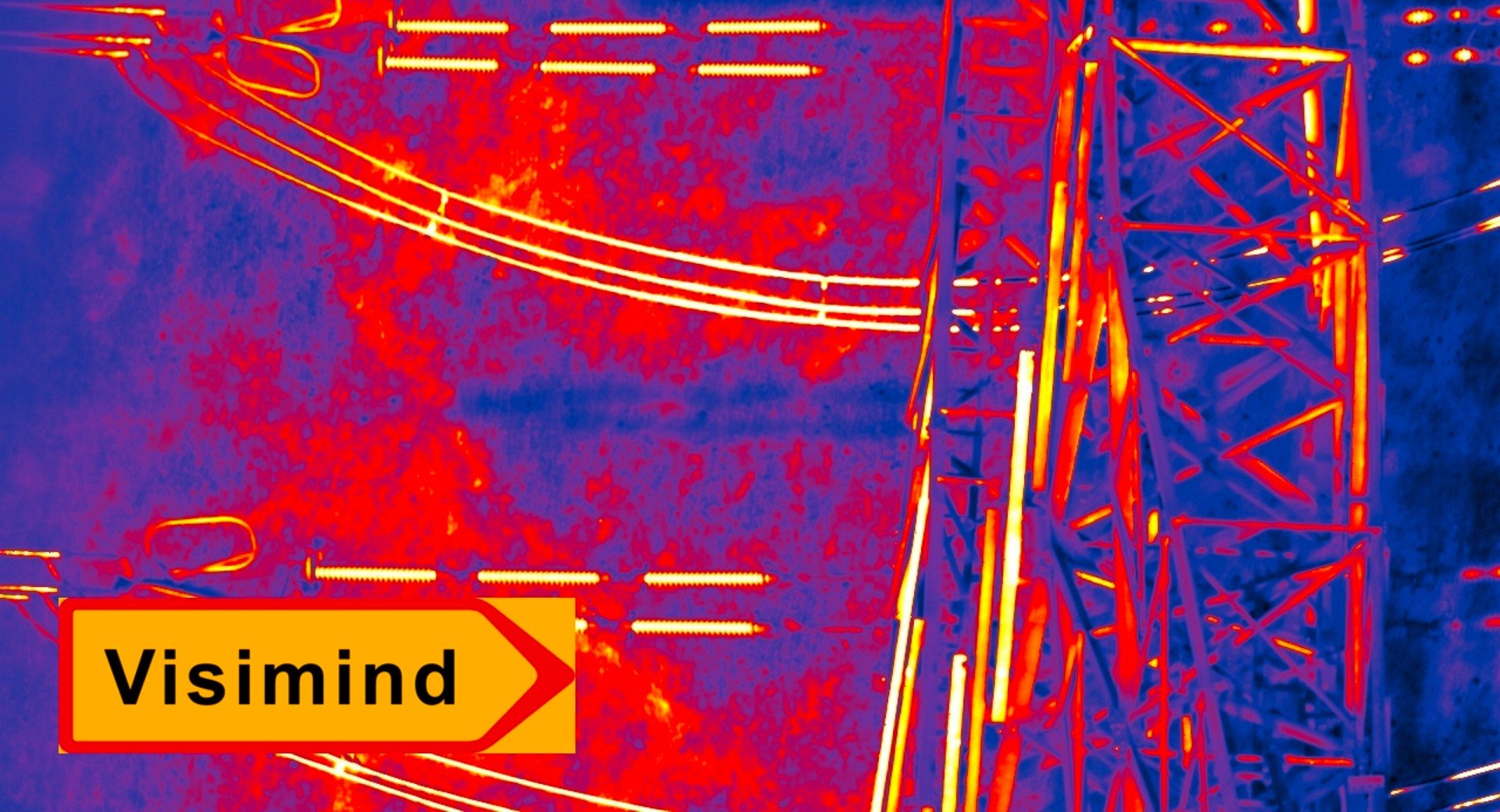

The high-performance device boasts a global shutter that can read each pixel simultaneously, while eliminating distortion or blurring; particularly crucial during motion capture.

Using the FLIR A8581’s precise temperature monitoring system, Visimind is able to safely inspect along power lines from the air, allowing for the early detection of potential thermal issues such as overloads (areas with elevated temperatures), loose connections, burnouts (areas with extremely high temperatures) and heat leaks.

Rapidly detecting damage with thermal imaging

The FLIR A8581 thermal camera allows for swift identification of various types of damage, including short circuits, corrosion of components and faulty insulators on power lines. By analysing temperature variations and anomalous heat pattern, problems are instantly apparent in affected areas - which is then reported to ensure prompt maintenance to preserve the power supply.

Advanced features: why the FLIR A8581 is ideal for electric utility inspections

FLIR A8581 cameras provide the crisp imagery, accurate temperature measurement, and streamlined analysis features needed for industrial, military, and manufacturing high demanding applications - and electricity utility inspections are no exception.

It combines image and temperature recording, enabling the creation of precise inspection reports. Add to this an expanded temperature range ensuring accurate monitoring in even the most extreme conditions and diverse color palettes, distance measurement tools, and area assessment features and users like Visimind ensure accurate analysis of data as it is captured, the powerful detector producing high definition thermal images of the clearest calibre in environments from -20°C to 350°C (-4°F to 662°F).

Rafał Sulejewski, Hardware Engineering Manager at Visimind, said: “The FLIR camera demonstrates remarkable resistance to adverse weather conditions and challenging surroundings, ensuring reliable performance in any situation.

“By integrating FLIR A8581 thermal cameras into our array of cutting-edge technology, Vismind has elevated our utility inspection capabilities to new heights, offering unparalleled accuracy and insight into our clients' critical infrastructure.”